Introduction of a digital code system in a large brewery

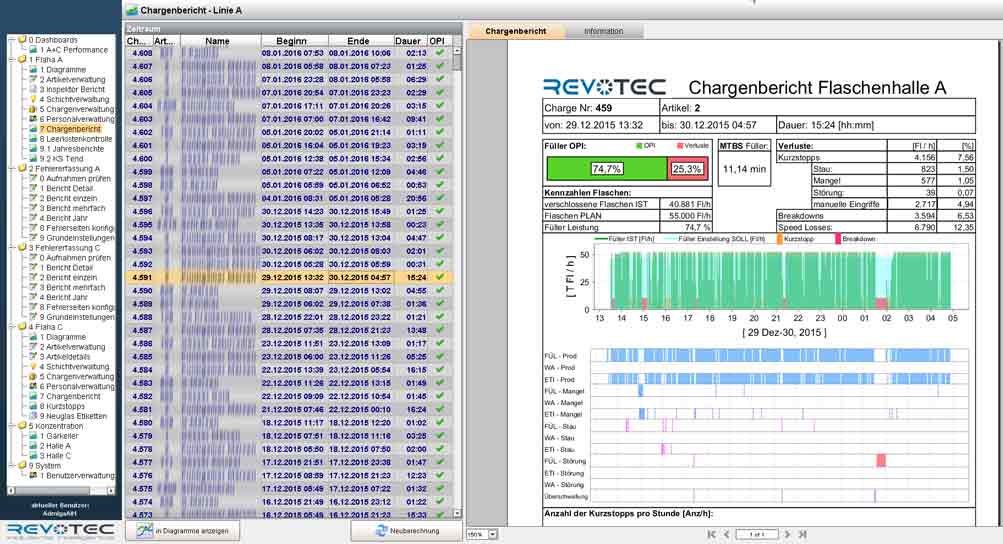

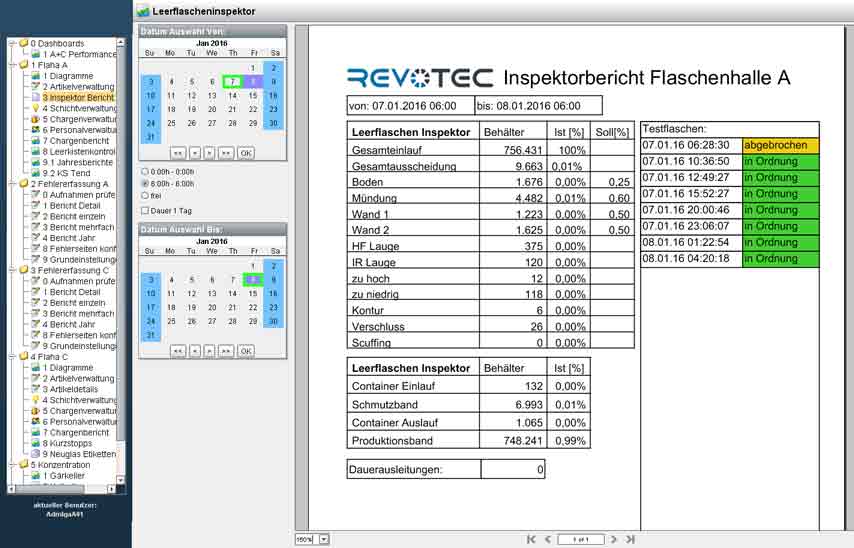

Manual calculation of standardized key performance indicators is time-consuming. We have automated this evaluation by means of a software solution. At the same time, we digitized run times and downtimes directly from the fieldbus level (PLC). The commissioning took place in stages, in order to integrate the employees’ experience in improving the software and to promote acceptance at the same time.

The automated evaluation includes standardized key performance indicators such as:

- OPI (operational performance indicator)

- Minor stop & speed loss

- MTBF (mean time between failure)

customer:

Objectives:

- Automated calculation of group-wide key performance indicators (OPI, MTBF, minor stops & speed loss)

- Step by step integration into the plant

Solution implemented:

- Dashboards with the most important key performance indicators

- Real-time data

- Online reports for the production manager

Key results:

- Clear assessment of plant efficiency

- Identification of improvement measures

- Basis for the KVP process and TQM